Links:

-

In conclusion, replacing the power steering hose in your Toyota Highlander is a task that can be accomplished with basic tools and a bit of mechanical knowledge. However, if you're unsure about any step of the process, it's always best to consult with a professional mechanic to ensure the job is done right. Regular checks and timely replacements will keep your Highlander's steering responsive and safe, enhancing your driving experience for many miles to come. Next, place a drain pan under the power steering pump to catch any power steering fluid that may leak out during the process. Use a socket set to remove the fittings attaching the power steering hose to the power steering pump and steering rack. Be sure to have a rag handy to wipe up any spilled fluid

e36 power steering hose diy. Not only does the spiral cord protector help to prevent damage, but it also helps to keep your earphones tangle-free. By keeping the cords neatly organized and straight, the protector reduces the likelihood of them getting tangled up in your bag or pocket. This makes it much easier to retrieve your earphones when you need them, without having to spend precious minutes untangling a knotted mess

spiral cord protector for earphone. Lastly, the company's commitment to sustainability is reflected in their power steering hoses. Impala uses eco-friendly production methods, reducing waste and minimizing the environmental impact. As consumers become more conscious about their carbon footprint, choosing an Impala hose demonstrates a responsible choice. One of the key advantages of using hose pipe end connectors is their versatility. They come in a wide range of sizes, shapes, and materials, making them suitable for use with different types of hoses and fixtures. Whether you need a connector made of brass, stainless steel, or plastic, there is sure to be one that meets your specific requirements. When it comes to automotive systems, the power steering hose is a crucial component that ensures smooth and efficient operation of the vehicle's steering system. This hose, which is typically made of high-pressure rubber or synthetic materials, is responsible for transmitting the hydraulic fluid from the power steering pump to the steering gearbox. In this article, we will delve into the intricacies of the 6.0%2520Power%2520Steering%2520Hose%2520Diagram, providing a comprehensive guide to help you understand its design, function, and maintenance requirements. The 25mm size of the coupler is significant as it caters to a common pipe diameter used in plumbing, water supply systems, and even gas lines. Its compact design allows for easy installation, making it a popular choice among plumbers and construction professionals. It can be tightened using standard tools, facilitating quick and efficient connections, which is particularly beneficial on busy job sites where time is of the essence It can be tightened using standard tools, facilitating quick and efficient connections, which is particularly beneficial on busy job sites where time is of the essence

It can be tightened using standard tools, facilitating quick and efficient connections, which is particularly beneficial on busy job sites where time is of the essence It can be tightened using standard tools, facilitating quick and efficient connections, which is particularly beneficial on busy job sites where time is of the essence

It can be tightened using standard tools, facilitating quick and efficient connections, which is particularly beneficial on busy job sites where time is of the essence It can be tightened using standard tools, facilitating quick and efficient connections, which is particularly beneficial on busy job sites where time is of the essence 25mm gi coupler. Next, you'll need to remove the old hose from the vehicle

25mm gi coupler. Next, you'll need to remove the old hose from the vehicle

98 silverado power steering hose replacement. This may require some maneuvering and twisting to get the hose out of the cramped spaces in the engine bay. Once the old hose is removed, you can then install the new power steering hose in its place. Be sure to secure the hose with the appropriate clamps and fittings to prevent any leaks. Air conditioning lines, often unseen but ever so crucial, form the lifeblood of modern buildings in our summer days. These intricate networks of pipes and conduits, carrying chilled refrigerant, silently weave their way through walls, ceilings, and floors, delivering comfort and respite from scorching temperatures. * Regular inspection Inspect the hose for any signs of damage, such as cracks, leaks, or bulges Some key maintenance tasks include Custom brake lines for cars are an essential upgrade for automotive enthusiasts seeking to enhance their vehicle's braking performance. These specialized brake lines, also known as stainless steel braided brake lines or performance brake lines, offer a significant improvement over the standard rubber hoses that come with most cars straight from the factory. Ignoring a power steering hose leak can lead to more severe issues down the line. The lack of power steering fluid can cause the power steering pump to overheat and fail, resulting in costly repairs. Additionally, driving with a leaky power steering hose can lead to a loss of steering control, putting you and others on the road at risk

nissan titan power steering hose leak. Understanding the S10 Power Steering Hose Diagram Why Does My Power Steering Hose Keep Blowing Off? One of the key advantages of sewer jetters is their versatility. They can be used in various environments, from residential homes to commercial complexes, municipal sewers, and even industrial settings. Their compact size enables them to navigate tight spaces and reach areas that would be inaccessible to larger equipment Their compact size enables them to navigate tight spaces and reach areas that would be inaccessible to larger equipment

Their compact size enables them to navigate tight spaces and reach areas that would be inaccessible to larger equipment Their compact size enables them to navigate tight spaces and reach areas that would be inaccessible to larger equipment

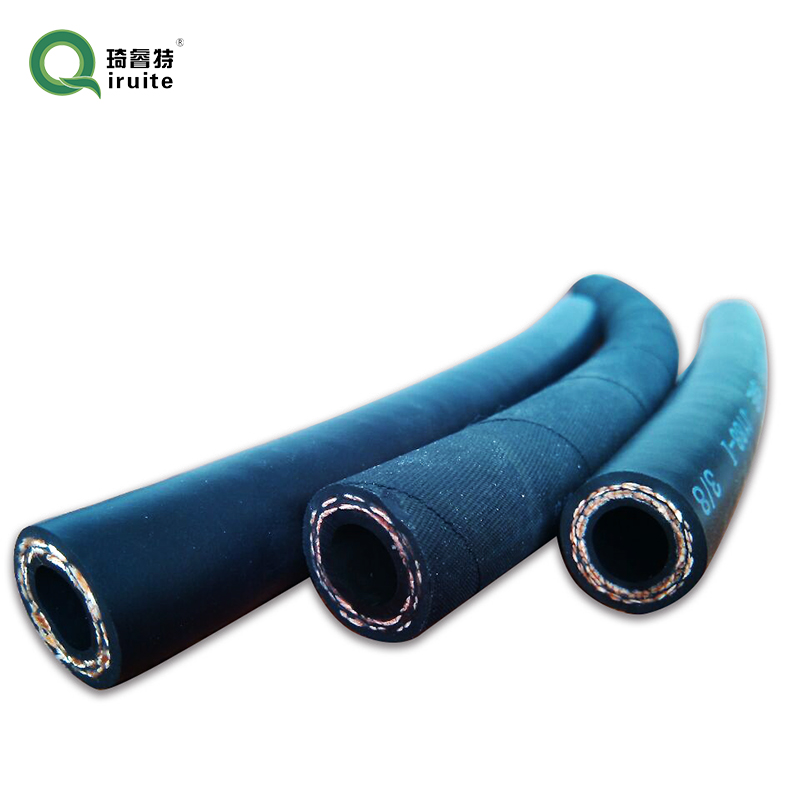

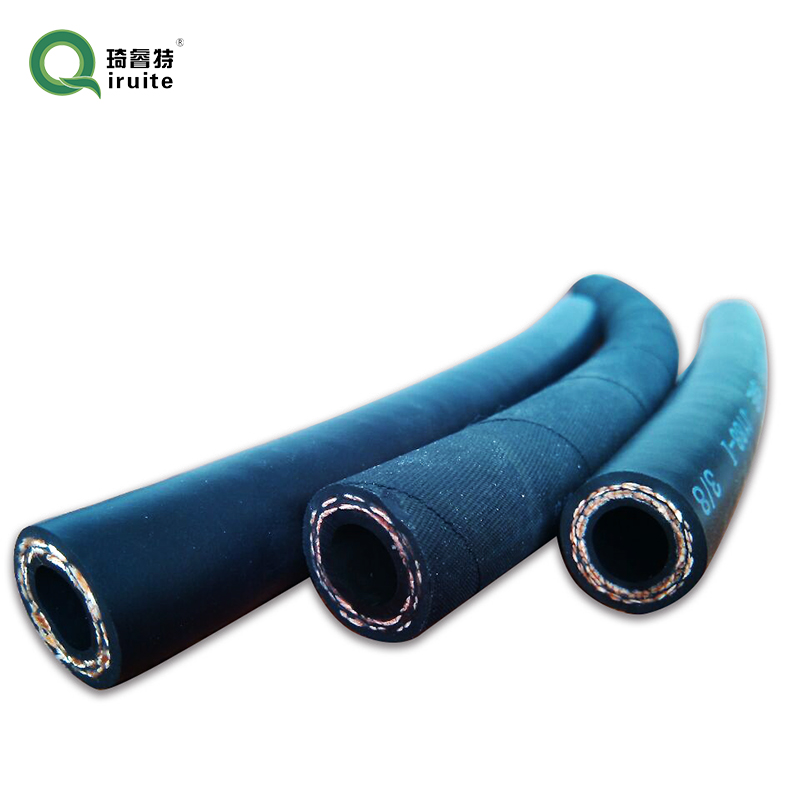

Their compact size enables them to navigate tight spaces and reach areas that would be inaccessible to larger equipment Their compact size enables them to navigate tight spaces and reach areas that would be inaccessible to larger equipment sewer jetter reel. Furthermore, they minimize the need for invasive physical excavation, saving time, money, and environmental impact. The power steering hose is a critical component of the power steering system, responsible for transmitting the hydraulic pressure generated by the engine to the steering mechanism. It is designed to withstand high pressures and temperatures, ensuring smooth and responsive steering. The hose is typically made of synthetic rubber or thermoplastic materials, which provide flexibility and durability. In conclusion, a portable air conditioner without a hose represents a significant advancement in the world of cooling appliances. It combines practicality, flexibility, and modern technology to provide a user-friendly and effective cooling solution. Whether you're looking to beat the heat in a rented apartment or add supplementary cooling to your existing system, these units offer a convenient and efficient alternative to traditional air conditioning. Embrace the comfort they bring and make your hot summer days a little more bearable. Overall, R134a hose is a critical component in automotive air conditioning systems, playing a key role in the safe and efficient operation of the system. By selecting a high-quality hose that is compatible with the refrigerant and properly maintaining it, drivers can enjoy reliable and comfortable cooling in their vehicles. With the right hose in place, the air conditioning system can continue to provide cool air on hot summer days for years to come. 4. Remove the old hose by gently pulling it off the connections while supporting the steering column to prevent damage. A pipe connector, by definition, is a device used to link two or more pipes together, allowing them to function as a single unit. In the case of a 10mm to 15mm pipe connector, its primary function is to bridge the gap between pipes with diameters of 10mm and 15mm. This adaptation is particularly useful in situations where resizing or adapting pipework is necessary due to design constraints or changing requirements.

sewer jetter reel. Furthermore, they minimize the need for invasive physical excavation, saving time, money, and environmental impact. The power steering hose is a critical component of the power steering system, responsible for transmitting the hydraulic pressure generated by the engine to the steering mechanism. It is designed to withstand high pressures and temperatures, ensuring smooth and responsive steering. The hose is typically made of synthetic rubber or thermoplastic materials, which provide flexibility and durability. In conclusion, a portable air conditioner without a hose represents a significant advancement in the world of cooling appliances. It combines practicality, flexibility, and modern technology to provide a user-friendly and effective cooling solution. Whether you're looking to beat the heat in a rented apartment or add supplementary cooling to your existing system, these units offer a convenient and efficient alternative to traditional air conditioning. Embrace the comfort they bring and make your hot summer days a little more bearable. Overall, R134a hose is a critical component in automotive air conditioning systems, playing a key role in the safe and efficient operation of the system. By selecting a high-quality hose that is compatible with the refrigerant and properly maintaining it, drivers can enjoy reliable and comfortable cooling in their vehicles. With the right hose in place, the air conditioning system can continue to provide cool air on hot summer days for years to come. 4. Remove the old hose by gently pulling it off the connections while supporting the steering column to prevent damage. A pipe connector, by definition, is a device used to link two or more pipes together, allowing them to function as a single unit. In the case of a 10mm to 15mm pipe connector, its primary function is to bridge the gap between pipes with diameters of 10mm and 15mm. This adaptation is particularly useful in situations where resizing or adapting pipework is necessary due to design constraints or changing requirements. In the early days of automobile history, steering required considerable muscle power from the driver, as the wheels had to be physically turned against the resistance of the tires and road friction. However, with the advent of power steering, a revolution took place in the drivability of cars. A power steering hose plays a pivotal role in this system by transporting pressurized fluid from the pump to the steering gearbox, enabling drivers to navigate with minimal effort. Moreover, the protection offered by the Spiral Wrap goes beyond physical damage 5. **Filling and Bleeding the System** After installing the new hose, refill the power steering fluid reservoir with the recommended type and amount of fluid. Start the engine and turn the steering wheel from lock to lock several times to bleed any air bubbles from the system. Check for leaks and top up the fluid level if necessary. Now, it's time to install the new power steering hose. Slide it into place, ensuring a snug fit at all mounting points. Tighten the connections securely but avoid over-tightening, which could damage the fittings. Refill the power steering reservoir with fresh fluid, following the manufacturer's guidelines for the correct type and amount. In the automotive sector, hose wrap spiral tubing is crucial for protecting fuel lines, brake lines, and electrical harnesses from chafing and damage due to constant movement and vibration. In construction, it safeguards hydraulic hoses from sharp edges and debris on job sites, enhancing safety and extending hose life. Agricultural machinery also benefits from this tubing, preventing wear and tear caused by constant exposure to soil, moisture, and rough terrain Agricultural machinery also benefits from this tubing, preventing wear and tear caused by constant exposure to soil, moisture, and rough terrain

Agricultural machinery also benefits from this tubing, preventing wear and tear caused by constant exposure to soil, moisture, and rough terrain Agricultural machinery also benefits from this tubing, preventing wear and tear caused by constant exposure to soil, moisture, and rough terrain

Agricultural machinery also benefits from this tubing, preventing wear and tear caused by constant exposure to soil, moisture, and rough terrain Agricultural machinery also benefits from this tubing, preventing wear and tear caused by constant exposure to soil, moisture, and rough terrain hose wrap spiral tubing. 1. Material As mentioned earlier, stainless steel and braided steel are popular choices due to their strength and durability. However, other materials such as aluminum or plastic may be suitable for certain applications or budgets. 1. Manufacturing Defects The crimp joint, where the hose is connected to the steering pump, can develop leaks due to inadequate or faulty manufacturing processes. If the crimp is too tight or too loose, it can lead to damage over time. R-134a, a widely used refrigerant in automotive and commercial air conditioning units, necessitates specific fittings to ensure a secure and leak-proof connection. The term 134a fitting size refers to the dimensions and thread specifications of the connectors designed to interface with R-134a refrigerant lines. It's not just about the physical size; it also involves the compatibility with the refrigerant's pressure and temperature characteristics. Preventative maintenance can significantly reduce the likelihood of developing a power steering hose leak. Regularly checking the fluid level and condition, along with inspecting the hoses for any signs of weakness or damage, can help catch potential issues early. Additionally, avoiding harsh driving conditions and minimizing exposure to extreme temperatures can prolong the lifespan of the hoses. One common type of coupling is called in coupling, which specifically refers to the number of incoming connections that a module has from other modules. In simpler terms, in coupling measures how many other modules are dependent on a particular module. The higher the in coupling, the more interconnected and dependent the modules are on each other. The Powerhouse of Sewer Jetters Revolutionizing Drainage Solutions The 07 Odyssey, known for its spacious interior and family-friendly features, is a popular choice among minivan enthusiasts. However, one component that often goes unnoticed but plays a crucial role in ensuring a comfortable and controlled driving experience is the power steering hose. In this article, we will explore the importance of the 07 Odyssey power steering hose and why it is essential for maintaining the performance and safety of your vehicle. Nissan Titan Power Steering Hose A Comprehensive Overview The choice of material for brake fluid lines is critical due to the high pressure and temperature changes they endure. Steel lines, for instance, are known for their durability and resistance to corrosion, making them ideal for harsh environments. On the other hand, synthetic lines offer flexibility and resistance to extreme temperatures, particularly in performance vehicles. Post-repair, it's essential to monitor the system for any further leaks and perform regular maintenance checks. Regular fluid changes and inspections can help prevent future issues and prolong the life of your power steering system. In addition to conventional mirrors, SAE J1401 also addresses advanced technologies like electrochromic (smart) mirrors and cameras, which are becoming more prevalent in modern vehicles To repair a car's AC rubber hose, the following steps are typically followed Replacing a power steering hose in a Kia vehicle can be a complex process that requires specific tools and expertise

hose wrap spiral tubing. 1. Material As mentioned earlier, stainless steel and braided steel are popular choices due to their strength and durability. However, other materials such as aluminum or plastic may be suitable for certain applications or budgets. 1. Manufacturing Defects The crimp joint, where the hose is connected to the steering pump, can develop leaks due to inadequate or faulty manufacturing processes. If the crimp is too tight or too loose, it can lead to damage over time. R-134a, a widely used refrigerant in automotive and commercial air conditioning units, necessitates specific fittings to ensure a secure and leak-proof connection. The term 134a fitting size refers to the dimensions and thread specifications of the connectors designed to interface with R-134a refrigerant lines. It's not just about the physical size; it also involves the compatibility with the refrigerant's pressure and temperature characteristics. Preventative maintenance can significantly reduce the likelihood of developing a power steering hose leak. Regularly checking the fluid level and condition, along with inspecting the hoses for any signs of weakness or damage, can help catch potential issues early. Additionally, avoiding harsh driving conditions and minimizing exposure to extreme temperatures can prolong the lifespan of the hoses. One common type of coupling is called in coupling, which specifically refers to the number of incoming connections that a module has from other modules. In simpler terms, in coupling measures how many other modules are dependent on a particular module. The higher the in coupling, the more interconnected and dependent the modules are on each other. The Powerhouse of Sewer Jetters Revolutionizing Drainage Solutions The 07 Odyssey, known for its spacious interior and family-friendly features, is a popular choice among minivan enthusiasts. However, one component that often goes unnoticed but plays a crucial role in ensuring a comfortable and controlled driving experience is the power steering hose. In this article, we will explore the importance of the 07 Odyssey power steering hose and why it is essential for maintaining the performance and safety of your vehicle. Nissan Titan Power Steering Hose A Comprehensive Overview The choice of material for brake fluid lines is critical due to the high pressure and temperature changes they endure. Steel lines, for instance, are known for their durability and resistance to corrosion, making them ideal for harsh environments. On the other hand, synthetic lines offer flexibility and resistance to extreme temperatures, particularly in performance vehicles. Post-repair, it's essential to monitor the system for any further leaks and perform regular maintenance checks. Regular fluid changes and inspections can help prevent future issues and prolong the life of your power steering system. In addition to conventional mirrors, SAE J1401 also addresses advanced technologies like electrochromic (smart) mirrors and cameras, which are becoming more prevalent in modern vehicles To repair a car's AC rubber hose, the following steps are typically followed Replacing a power steering hose in a Kia vehicle can be a complex process that requires specific tools and expertise

kia power steering hose. It is recommended to have the hose replaced by a qualified mechanic or Kia service center to ensure proper installation and functionality. Additionally, it is important to use high-quality replacement hoses to ensure long-lasting performance and reliability. A Mercruiser power steering hose adapter serves as a bridge between the power steering pump and the steering cylinder or helm, facilitating the transfer of hydraulic fluid under pressure. The primary function of these adapters is to ensure a secure and leak-proof connection, thereby enhancing the overall steering efficiency and safety of the vessel. When the power steering hose fails, it can cause a range of problems. The most obvious symptom is a noticeable decrease in the vehicle's steering assist, making it harder to turn the wheel. This can be particularly dangerous when driving at high speeds or in tight spaces, as it can significantly reduce the driver's ability to control the vehicle. In addition, a leak in the power steering hose can also cause the fluid to spray onto the ground, creating a slippery and hazardous driving surface. When selecting a new TSX power steering hose, it's important to consider factors like compatibility, material quality, and manufacturer warranty. Always opt for genuine parts or high-quality aftermarket alternatives to ensure longevity and reliable performance. In the realm of automotive engineering, the role of a power steering hose cannot be overstated. It is the unsung hero that enables smooth and effortless steering, translating driver's commands into precise vehicle movements. When we delve into the specialized domain of K Tuned power steering hoses, we uncover a level of performance enhancement and durability that takes this essential component to new heights. Fortunately, replacing the power steering hose is a relatively straightforward process that can be done by a qualified mechanic Over time, the power steering hose can become worn or damaged, leading to leaks and reduced efficiency. This not only affects the vehicle's performance but can also result in increased fuel consumption and noise from the steering system. The power steering hose O-Ring is located between the power steering hose and the power steering pump or the steering gear box. Its primary function is to create a seal that prevents leaks and maintains the proper pressure within the power steering system. Without this O-Ring, the power steering fluid would leak out, leading to a loss of power steering assist and potentially causing damage to other components in the system. Factors Affecting Swift Car AC Pipe Price Split AC water outlet pipe price can vary depending on a number of factors. In general, the price range for a water outlet pipe for a split AC system can range anywhere from $10 to $50. This range may seem wide, but there are several factors that can influence the cost of a water outlet pipe. Constructed from premium materials, these hoses are engineered to endure extreme pressure fluctuations that occur within the power steering system. They are typically made from high-quality synthetic rubber, reinforced with multiple layers of steel wire braid, ensuring durability and resistance to leaks or bursts. These robust hoses can handle pressures well over 3,000 psi, making them suitable for high-performance vehicles and heavy-duty applications. 3. Remove the old vacuum line by cutting it at both ends and pulling it off.